Backflow prevention protects our drinking water from contamination. I work with North Fort Myers Plumbing Inc. to keep systems safe and reliable. We inspect devices to catch issues before they grow. Regular care reduces emergencies and repair costs. Testing verifies that each device meets safety standards.

Understanding Backflow Prevention

What is Backflow?

Backflow happens when water flows in the reverse direction. Pressure drops cause water to move backward unexpectedly. Contaminants may enter clean water lines through cross-connections. Poor plumbing design further increases backflow risks. Homeowners face serious health hazards when backflow occurs.

The Function of Backflow Preventers

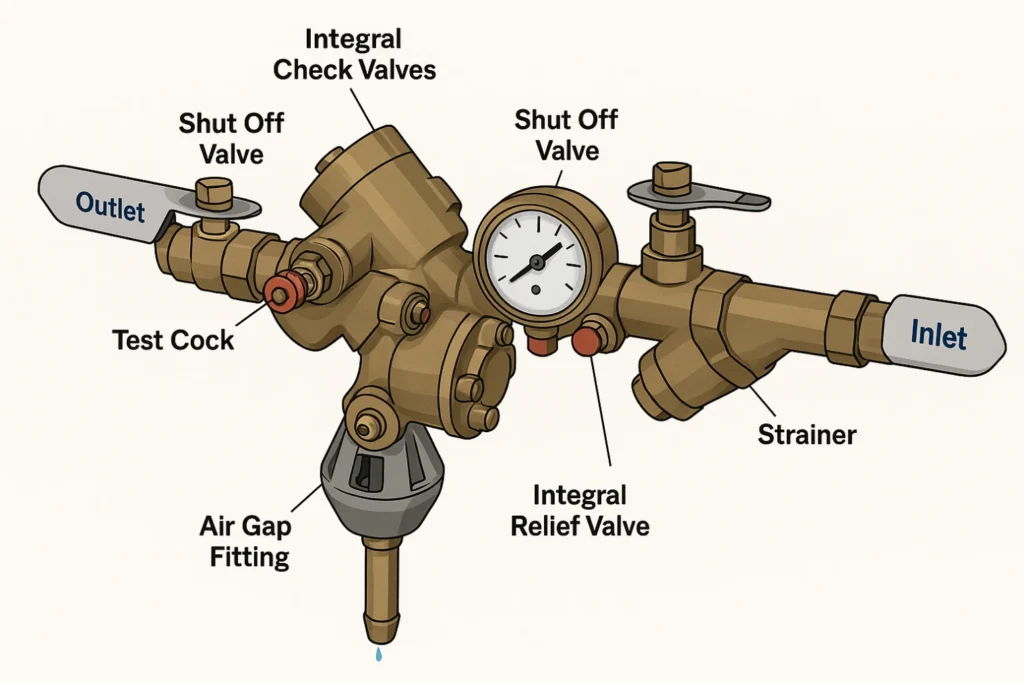

Backflow preventers stop water from reversing its intended path. They use check valves, air gaps, and relief valves to block contaminants. Devices monitor pressure changes to maintain safe operation. They activate immediately when abnormal pressure appears. These systems keep water clean and dependable.

The Importance of Regular Maintenance and Testing

Health and Safety Implications

Faulty backflow systems expose homes to dangerous contaminants. Leaks and device failures can allow harmful chemicals and bacteria into water. Regular maintenance keeps systems secure and prevents health risks. Testing detects issues before they threaten public safety. For further information on the risks of contaminated water, see the CDC’s page on Waterborne Diseases.

Regulatory and Compliance Requirements

Local codes require annual tests on backflow devices. State regulations enforce strict testing schedules that all systems must follow. Certified professionals perform these tests to ensure compliance. Non-compliance may lead to fines and service interruptions. We follow every regulation to protect our customers. For example, the EPA Drinking Water Regulations set national standards for water quality.

Economic and Long-Term Benefits

Routine maintenance saves money by avoiding emergency repairs. Regular tests extend a device’s lifespan and improve reliability. Early repairs stop minor issues from becoming costly. Reliable devices add value to your property. Customers benefit from lower long-term costs and fewer disruptions.

Detailed Testing Procedures for Backflow Preventers

Overview of Testing Methodologies

Testing confirms that devices operate as they should. Professionals simulate backflow conditions during each test. They measure pressure differences with precise instruments. Each test verifies that the device stops reverse flow. This process detects problems early and ensures safety.

Tools and Equipment Used

Inspectors use differential gauges to measure pressure accurately. They deploy three-valve and five-valve test kits to capture subtle variations. Specialized tools help record small pressure changes precisely. Certified technicians handle equipment with professional care. Educational resources from the USC Foundation for Cross-Connection Control and Hydraulic Research provide in-depth guidance on testing procedures.

Step-by-Step Testing Process

Inspectors shut off the water before starting the test. They flush the test ports to remove debris and air pockets. Professionals attach hoses to the device’s test cocks and measure pressure. They record each measurement carefully during the process. Every step confirms that the device works correctly.

Comprehensive Maintenance Strategies

Visual Inspection and Cleaning Techniques

Technicians inspect each device for leaks and signs of corrosion. They examine valve alignments and secure connections meticulously. Workers clean off scale and remove debris from critical parts. Regular inspections reveal early wear and prevent failures. Proper cleaning ensures smooth device operation.

Scheduled Testing and Performance Evaluations

Maintenance plans include regular testing and performance reviews. Scheduled checks ensure devices operate at peak efficiency. Professionals follow manufacturer guidelines to set testing intervals. Timely evaluations stop minor issues before they escalate. Our team organizes annual service reminders for every customer.

Record-Keeping and Documentation Practices

Technicians record every inspection and test in detailed logs. They document repairs and maintenance activities accurately. Clear records support compliance with local regulations. Detailed documentation helps plan future service and troubleshooting. Effective record-keeping improves overall water system management.

3 Practical Tips

Schedule inspections and tests on a regular calendar. Address minor issues immediately to prevent costly failures. Build a trusted relationship with a certified backflow specialist. Keep clear records to track each maintenance event. Follow manufacturer instructions during routine upkeep.

Frequently Asked Questions

What are the common signs that my backflow preventer needs maintenance?

You may notice leaks or damp spots around the device. Unusual water pressure fluctuations may signal an issue. Visible corrosion or worn parts indicate that care is needed. A strange noise during water use may point to malfunctioning valves. A professional inspection can confirm these signs and recommend repairs.

How often should a backflow preventer be tested in a residential or commercial setting?

Most systems require testing on an annual basis for safety. Commercial properties sometimes need tests more frequently due to higher risks. Local regulations usually determine the exact testing schedule. Certified technicians perform these tests with reliable methods. Regular testing ensures continuous compliance with safety standards.

What are the key differences between the various types of backflow prevention devices?

Air gaps create a physical separation between water sources. Vacuum breakers introduce air to break the siphon effect. Check valves allow water to flow in only one direction. Reduced pressure zone devices offer extra safety with redundant components. Each device suits different plumbing setups and risk levels.

Can routine backflow testing be performed as a DIY project, or should it always be handled by a professional?

Routine testing requires specialized tools and precise techniques. DIY tests often miss subtle failures or misread pressure changes. Certified professionals offer accuracy and detailed documentation. Professional testing ensures compliance with local codes and regulations. Hiring experts protects your water supply and saves you from costly mistakes.

Practical Applications and Future Considerations

Integrating Backflow Maintenance into Overall Plumbing Care

Incorporate backflow testing into your overall plumbing maintenance schedule. Coordinate tests with other inspections to save time and effort. A combined approach improves system efficiency and prevents oversights. Integrating care routines enhances overall plumbing reliability. Our team supports a comprehensive strategy for water safety.

Technological Advancements in Testing and Monitoring

Digital gauges now improve testing accuracy and speed. Remote monitoring systems provide real-time pressure data. Modern technology detects subtle issues with greater precision. Software tools simplify record-keeping and send maintenance alerts. These innovations boost long-term system reliability and user confidence.

Preparing for Evolving Regulations and Standards

Regulations change to ensure water safety continuously. Stay informed by reviewing local code updates frequently. Attend professional workshops to learn about new standards. Adjust your maintenance schedule as regulations evolve. Our experts update our practices to meet current requirements.

Key Takeaways

Backflow devices protect our water from harmful contaminants. Regular maintenance keeps systems reliable and compliant. Testing confirms proper function and prevents failures. Preventative care saves money and reduces emergency repairs. I encourage proactive care to maintain safe water for all.