Takeaways

- Lee County now requires annual irrigation backflow testing with a 7-day report submission deadline after inspection.

- Homeowners must hire certified testers, upload results via LCU’s portal, and act quickly to avoid service disruptions.

- Warning signs like valve weeping or pressure loss signal device issues that require immediate professional attention.

Why Annual Backflow Testing Matters in Southwest Florida

Protecting Household Water Quality

Annual backflow testing safeguards the water you drink every day. Local lawns often host reclaimed water and fertilizer, so irrigation lines pose real contamination risks. Therefore, a reliable assembly keeps lawn chemicals from migrating into kitchen taps. Homeowners enjoy peace of mind because certified testers verify device integrity each year. Consequently, families avoid boil-water notices and expensive plumbing emergencies. Pairing compliant irrigation devices with whole-house water filtration systems further protects drinking water.

Timeline of Florida Irrigation-Backflow Rules

State guidelines long required testing every two years, yet counties now tighten schedules. Lee County updated its cross-connection policy in May 2024, shifting to yearly inspections (source). Cape Coral enforced similar vigilance sooner, linking dual-water permits to certified devices. Therefore, residents now navigate stricter timelines when scheduling compliance work. This evolving timeline underscores the importance of staying informed.

Increased Oversight by Local Utilities

Utilities created online portals that track every assembly in real time. Inspectors review uploads quickly and flag missing reports almost immediately. Consequently, late filings invite warnings, retest orders, and possible shutoffs. Homeowners must plan ahead because enforcement now relies on digital timestamps. Therefore, proactive scheduling prevents costly interruptions.

Understanding the New Requirements

Lee County Utilities Cross-Connection Policy (May 2024)

Lee County now mandates yearly certification for every residential irrigation backflow device (source). The policy also shortens the report window to seven calendar days after testing. Consequently, technicians must submit results online before the deadline expires. Failure triggers automatic retest notifications and potential water-service suspensions. Therefore, residents benefit when they hire organized professionals familiar with the portal.

Cape Coral’s Dual-Water Permit Ordinance

Cape Coral requires an approved backflow assembly before issuing any dual-water permit. Inspectors verify device type and test date during each permit review. Non-compliant properties risk immediate permit denial and service interruption. Therefore, homeowners planning new landscaping must schedule tests early in the project. Quick action keeps construction timelines intact.

From Biennial to Annual: How the Schedule Tightened

Utilities tightened schedules because data revealed rising irrigation cross-connection incidents. Annual tests catch worn parts before failures contaminate public lines (source). Therefore, counties moved from biennial cycles to yearly checks for higher protection. Homeowners now adjust budgets to include consistent testing fees. Consequently, the region experiences safer water and fewer emergency flushes.

Device Basics for Home Irrigation Systems

Key Backflow Assembly Types and Their Uses

Irrigation systems rely on three common assemblies: double-check valves, pressure vacuum breakers, and reduced-pressure principle assemblies. Double-check valves suit low-hazard zones with potable lines only. Pressure vacuum breakers protect systems above grade where freeze risk remains low. Reduced-pressure assemblies cover high-hazard sites with reclaimed water or fertilizer injectors. Understanding each type helps homeowners pick the right protection.

Use this quick-reference guide to better understand the differences between the most common residential devices.

| Device Type | Typical Use | Test Frequency | Installation Location | Expected Lifespan |

|---|---|---|---|---|

| Double Check Valve Assembly (DCVA) | Low-hazard irrigation with potable water only | Every 2 years (some jurisdictions) | Below-grade or indoors | 15–20 years |

| Pressure Vacuum Breaker (PVB) | Sprinkler systems above grade with no fertilizer injection | Every 1–2 years | At least 12” above highest outlet | 12–15 years |

| Reduced Pressure Principle Assembly (RP) | High-hazard systems with reclaimed water or fertilizer injection | Every year (mandated) | Above-grade with drainage access | 10–15 years |

Why Reduced-Pressure Principle (RP) Assemblies Dominate Lawn Installations

Southwest Florida lawns often use reclaimed water and chemical feeders, so RP assemblies provide the safest barrier. They vent pressure changes quickly, preventing back-siphon events during power outages. Therefore, utilities prefer RP devices near meters for irrigation services. Homeowners enjoy robust protection and straightforward testing procedures. Annual checks then confirm relief mechanisms operate correctly.

Choosing the Right Device for Fertilizer or Reclaimed-Water Exposure

Garden fertilizer injectors introduce nutrients that can flow backward when pressure drops. Reclaimed lines also carry higher bacterial loads than potable sources. Consequently, only RP assemblies meet code for such conditions. Certified plumbers evaluate site elevation, chemical use, and supply pressure before recommending devices. Proper selection ensures long-term compliance and reliable operation.

Step-by-Step Compliance Guide for Homeowners

Locating the Irrigation Backflow Assembly on Your Property

Begin at the irrigation meter near the street and follow the lateral line inward. Look for a bronze or plastic valve set within a green rectangular box. RP devices feature a relief port that faces downward and often drips briefly after cycles. Use a flashlight to read the model label and last test tag attached. Document the location with a smartphone photo for future reference.

Scheduling an Annual Test with a Certified Technician

Search utility-approved vendor lists published by Lee County and neighboring cities. Next, request proof of certification and current calibration records for test gauges. Schedule visits early in spring because calendars fill quickly before rainy season begins. Remind technicians to tag the device and supply a digital report on completion day. Quick coordination avoids last-minute scramble and late fees.

Submitting Digital Test Reports Through LCU’s Online Portal

Technicians upload results through the BSI portal using property account numbers. Homeowners then receive confirmation emails that show pass or fail status immediately. Verify entries for spelling errors or incorrect serial numbers before logging off. Save the PDF receipt in a dedicated home-maintenance folder on cloud storage. These records support warranty claims and simplify next year’s appointment (source).

Warning Signs the Device Needs Service

Visual Red Flags: Valve Weeping, Continuous Relief Discharge

Observe the assembly weekly when mowing or edging near the box. Continuous drips from the relief port often indicate worn seals that compromise protection. Rust streaks on brass bodies suggest corrosive soil or stagnant water pooling. Broken test-cock caps expose internals to insects and debris. Early repairs prevent full replacements later.

Performance Indicators: Sudden Pressure Loss, Unusual Sprinkler Patterns

Notice sprinkler heads sputtering or failing to pop up during normal cycles. Check for unexpected low pressure at outdoor bibs connected downstream of the device. These symptoms signal internal blockages restricting flow. Schedule a certified test immediately if pressure drops persist across multiple zones. Timely intervention limits lawn stress and expensive landscape repairs. Professional leak detection pinpoints hidden cross-connections when pressure drops without visible leaks.

Maintenance Logging and When to Call a Professional

Record every inspection date, observed issue, and corrective action in a simple spreadsheet. Include photos to track corrosion or vegetation growth around the box. Call a licensed backflow specialist whenever relief valves leak continuously despite flushing. Technicians can rebuild assemblies and reseal test cocks quickly. Regular documentation supports warranty claims should failures recur.

3 Practical Tips

- Set a smartphone alert thirty days before your device’s test tag expires so scheduling stays easy.

- Clear mulch and tall grass around the valve box to give technicians quick, safe access during inspections.

- Email test receipts to yourself and your utility account to ensure instant, searchable proof of compliance.

Penalties and Enforcement Actions

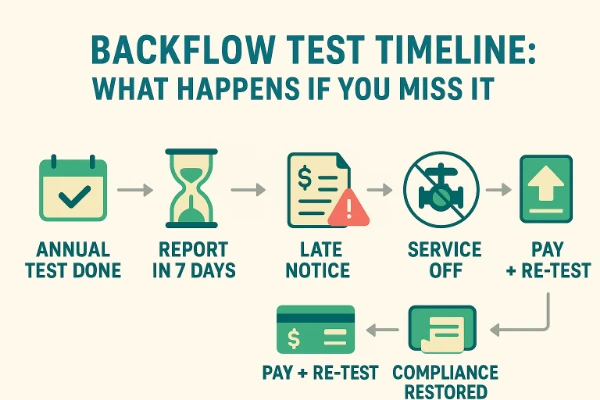

Non-Compliance Fees, Retest Orders, and Service Interruptions

Utilities charge escalating fees for late or missing certifications. They also issue formal retest orders that include strict completion dates. Ignoring notices triggers water-service shutoffs until passing results post online. Restoration requires additional fees plus proof of completed work. Staying proactive keeps bills predictable.

How to Respond to a Utility Notice of Violation

Read the notice carefully and mark all listed deadlines on your calendar. Contact an approved tester immediately and explain the urgency. Upload new results within the specified timeframe, then confirm receipt with utility staff. Keep email chains as documentation should future disputes arise. Prompt action usually lifts penalties quickly.

Pathways for Appeals or Extensions

Homeowners can request extensions when parts shortages or natural disasters delay repairs. Utility managers review written petitions that outline reasons and proposed completion dates. Provide contractor quotes or photos to strengthen the appeal. Temporary waivers typically last thirty days when evidence appears credible. Clear communication maintains goodwill.

Resources for Staying Compliant

Approved Tester Lists and Vendor Directories

Lee County Utilities publishes a searchable directory updated monthly. Cape Coral offers a downloadable PDF with license and insurance details. JEA covers statewide vendors, helpful for snowbirds managing multiple properties. Bookmark these pages for quick contractor comparisons. Regularly verify your chosen tester’s status before scheduling. Local plumbers offering professional backflow preventer services can handle the annual test and submit reports on your behalf.

Utility Portals: Upload Guides and Account Dashboards

LCU uses the BSI Online platform, while Cape Coral relies on SwiftComply. Both portals provide video tutorials demonstrating step-by-step uploads. Dashboards display upcoming due dates and historical results for each property. Enable email alerts so you never miss a deadline. Portal familiarity streamlines annual compliance.

Community Workshops and Certification Courses

Local utilities partner with extension offices to host irrigation safety workshops every spring. Sessions cover device basics, testing protocols, and portal navigation. Certified testers often demonstrate gauge calibration live. Homeowners gain hands-on experience and valuable maintenance tips. Attendance sometimes earns small bill credits. Seasonal drain cleaning prevents yard debris from clogging test-cock outlets.

FAQ — Annual Irrigation-Backflow Testing

How do I know if my irrigation system already has a certified backflow device?

Locate the valve box near your irrigation meter and inspect the tag attached to the assembly. The tag lists test dates, device type, and technician credentials. Annual tags should display a pass stamp less than twelve months old. If you find no tag or unreadable information, schedule a certified test immediately. Quick action secures compliance and protects water quality.

What happens if my backflow assembly fails the annual test?

The technician explains failure reasons and provides an itemized repair estimate. Many assemblies only need new check springs or seal kits, keeping costs manageable. After repairs, the tester submits a passing report through the utility portal. Keep both the failed and passed reports for your records. Documentation proves swift corrective action to city inspectors.

Can the same technician both repair and certify the device?

Yes, Florida allows certified backflow testers to perform repairs and retests on residential assemblies. Always confirm the technician holds both a plumbing license and backflow certification. Ensure they use calibrated gauges documented within one year. Request copies of calibration certificates for your maintenance file. Using one provider simplifies scheduling and accountability.

How much does an annual residential backflow test typically cost?

Most Southwest Florida vendors charge between sixty and one hundred dollars per device. Prices vary based on travel distance, device accessibility, and urgency. Repairs or rebuild kits add material costs, usually starting around thirty dollars. Bundling neighbor appointments sometimes lowers individual fees. Request multiple quotes to secure fair, competitive pricing.

Key Takeaways for Hassle-Free Compliance and Safer Water

Annual backflow testing now stands as a mandatory task for every Lee County and Cape Coral homeowner. Scheduling certified inspections early and uploading reports promptly prevent penalties and service disruptions. Regular device checks protect household water from lawn chemicals and reclaimed supply lines. Organized records and proactive maintenance keep landscapes healthy while wallets stay safe. Consistent action today secures reliable, clean water for your family tomorrow.

- Addressing Low Water Pressure in Older Florida Homes: Diagnosis, Solutions, and When to Call a Plumber - December 11, 2025

- Chloramine in Lee County Water: Understanding Its Impact on Rubber Gaskets, Water Heater Elements, and Plumbing Lifespan. - December 4, 2025

- Plumbing Durability for SWFL Rental Properties: Choosing Fixtures and Systems That Withstand High-Occupancy Wear and Tear - November 25, 2025