Takeaways

- Safety upgrades like T&P valves, mixing valves, expansion tanks significantly reduce household risk.

- Regular maintenance and inspections prevent pressure failures, scalds, Legionella, and tipping hazards.

- Matching upgrades to local codes ensures insurance compliance and improves system reliability.

Why Water Heater Safety Can’t Be an Afterthought

We at North Fort Myers Plumbing Inc. see hot water as comfort and risk. Outdated heaters can scald children, leak gas, or even burst under pressure. Modern safety upgrades protect families, meet insurance requirements, and save unexpected repair costs. Local codes increasingly demand proactive improvements rather than simple repairs after failures occur. This guide explains every upgrade step so homeowners stay safe, compliant, and confident.

Understanding Safety Risks in Older Water Heater Systems

Scalding Dangers from High Outlet Temperatures

Water exiting above 120 degrees Fahrenheit can burn skin in seconds. Children and older people face greater injury risk because their skin reacts faster. Many aging thermostats drift upward, allowing hidden temperature creep without warning. We install mixing valves to blend cold water and stabilize outlet temperatures. Simple thermometer checks at faucets help homeowners confirm safe temperatures each month.

Pressure Build-Up and Explosion Hazards

Thermal expansion raises tank pressure every time burners cycle or elements heat water. Without a relief path, steel walls eventually rupture with violent force. We see telltale whistling or dripping long before catastrophic failure occurs. Installing a functional T&P valve and expansion tank releases excess pressure safely. Homeowners should never plug or cap relief lines, even during minor leaks.

Carbon Monoxide Leaks from Poor Venting

Gas heaters rely on unobstructed flues to carry exhaust outdoors. Bird nests, collapsed liners, or back-drafts can send gases into living areas. Carbon monoxide displaces oxygen, causing dizziness, headaches, and life-threatening poisoning. We inspect draft hoods, flue joints, and roof caps during every service call. Installing detectors near bedrooms adds another protective layer for occupants.

Legionella Growth in Improperly Heated Water

Legionella bacteria thrive between 68 and 113 degrees Fahrenheit inside stagnant tanks. Under-heated storage promotes colonization, especially when sediment blankets the bottom. We set storage temperatures near 140 degrees Fahrenheit while delivering tempered water. Periodic flushing removes debris and interrupts bacterial habitats. The CDC recommends maintaining storage above 140°F and delivery above 120°F to control bacterial growth.

Tipping Risks During Earthquakes or Flood Events

Earthquakes and rising floodwaters can topple tall, heavy water heaters quickly. Ruptured gas lines or spilled scalding water compound the immediate danger. Seismic straps anchor tanks to framing, limiting lateral and vertical movement. We install upper and lower straps with heavy bolts set into studs. California’s Seismic Safety Commission confirms legal mandates for tank bracing during installation or sale.

Safety Component Upgrades That Make a Difference

T&P Valve (Temperature and Pressure Relief Valve)

The T&P valve senses both internal pressure and water temperature simultaneously. It opens at roughly 150 psi or 210 degrees Fahrenheit, whichever occurs first. We always match valve rating to tank stamping to ensure compatibility. A full-size discharge line runs downhill, ends openly, and never uses threads. Annual testing confirms smooth operation and dislodges mineral buildup.

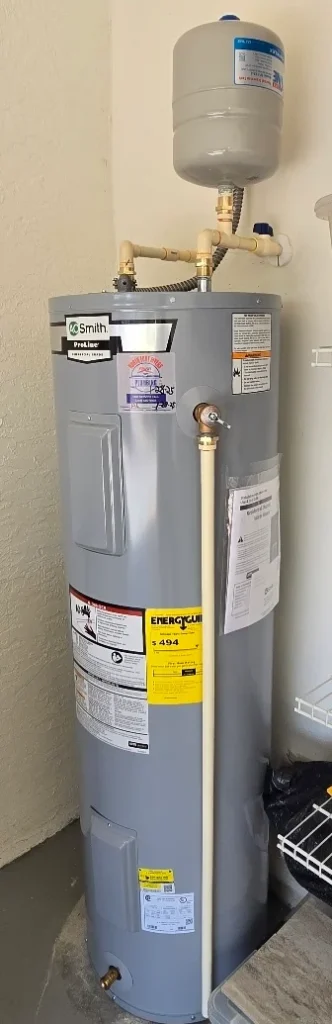

Thermal Expansion Tank

Closed plumbing systems trap heated volume, pushing pressure toward dangerous levels. An expansion tank contains an air bladder that compresses and absorbs excess pressure. We size the tank based on water volume and household pressure conditions. Proper inflation, usually near the incoming pressure, maximizes bladder longevity. Homeowners can tap the tank lightly; a hollow sound confirms correct air charge.

Anti-Scald Mixing Valves

Thermostatic mixing valves blend hot and cold streams to maintain consistent output. We locate valves near the heater to protect every downstream fixture instantly. Adjustment dials let homeowners fine-tune comfort without risking pathogen growth inside the tank. Regular cleaning prevents mineral deposits from narrowing internal passages and altering settings. Clear plastic indicating caps help families verify the selected temperature at a glance.

Seismic Restraint Systems

Florida rarely shakes like California, yet hurricane winds also jolt equipment. Seismic restraints use heavy-gauge metal straps positioned at the upper third and lower third. We anchor straps with lag bolts driven directly into wall studs or masonry. Rubber isolation blocks prevent strap edges from gouging the tank jacket. Sonoma County’s official code guide details proper strap placement and spacing.

Proper Venting & Combustion Air Access

Combustion consumes oxygen and produces exhaust that must exit the home safely. We measure draft strength with a manometer, confirming adequate negative pressure. Blocked vents cause soot, yellow flames, and dangerous carbon monoxide accumulation. Modern power-vent or direct-vent models offer sealed combustion and flexible routing. Adequate makeup air through louvered doors or dedicated ducts completes the system.

Drip Pan and Drain Line Protection

A simple drip pan catches minor leaks before they soak floors and walls. We install pans under heaters located above finished spaces or equipment. The attached drain line routes water outdoors or into a suitable receptor. Proper pan sizing and rigid materials prevent warping under tank weight. Regular inspections confirm the drain line remains clear and pitched correctly.

Garage Installation Elevation Rules (Gas Units)

Gas fumes from gasoline or solvents linger near garage floors. Ignition sources should stay above eighteen inches to avoid vapor ignition. We lift gas heaters onto sturdy platforms that support the full tank weight. Many municipalities also require bollards or wheel stops to prevent vehicle impact. Elevating the heater additionally improves access for servicing and cleaning.

Electrical Safety for Electric Units

Electric heaters demand a dedicated breaker and correctly sized copper conductors. Loose connections create arcing that melts terminals and starts fires. We tighten lugs to manufacturer torque specs and verify ground continuity. Bonding hot and cold pipes equalizes potential and reduces corrosion risk. Surge protection also shields delicate electronic controls found on hybrid models.

Matching Your System to Local Plumbing Code Requirements

Building departments publish specific rules that often exceed national model codes. We always pull permits and schedule inspections to verify compliance. Homeowners who attempt unpermitted work risk fines, insurance denials, and safety hazards. Our licensed plumbers check code-critical items like water pressure, seismic restraints, and required backflow preventer services before recommending upgrades. Documented compliance increases property value and ensures smooth resale transactions later.

Maintenance Strategies That Improve Water Heater Safety

Sediment Flushing and Why It Matters

Mineral-rich Florida water leaves lime and sand at the tank bottom. Sediment insulates burners, raises operating costs, and shortens tank life. We attach a garden hose, open the drain valve, and flush debris annually. Homeowners can schedule mid-year flushes when water appears rusty or smells unpleasant. Regular flushing maintains efficient heating and reduces noise from popping or rumbling.

TPR Valve Testing Best Practices

Lifting the TPR lever confirms internal spring movement and clear discharge piping. Water should flow freely and stop instantly when the lever releases. We test valves during every inspection and record results for warranty purposes. Excessive dripping afterward signals mineral buildup or weakened springs needing replacement. Replacing a faulty valve costs little compared with flood or explosion damage.

Annual Inspection Checklist for Homeowners

Visual checks uncover leaks, scorch marks, or loose connections early. We encourage homeowners to inspect straps, valves, and vent pipes each spring. Listening for hissing sounds can reveal pressure issues before serious failures. Draining a few gallons through the valve samples water clarity and sediment load. If recurring corrosion or low pressure affects performance, a full inspection may reveal the need for professional repiping services.

When to Replace vs When to Retrofit Components

Tank age, corrosion level, and warranty status influence replacement decisions. We suggest water heater replacement once tanks exceed ten years or show extensive rust. Younger units with solid shells often benefit from strategic retrofits like expansion tanks. Energy rebates sometimes offset costs, making full replacement financially attractive. We present clear options and let homeowners choose based on budget and goals.

Last year, we inspected a 14-year-old water heater that had never been flushed or serviced. The homeowner had no signs of leaks, but when we tested the T&P valve, nothing came out. Internally, the valve was clogged with hardened scale, and the expansion tank had ruptured. In cases like that, retrofitting isn’t just unsafe—it’s a liability. We replaced the unit and installed a full upgrade package with seismic strapping, a mixing valve, and a new expansion tank.

The table below shows recommended inspection and testing intervals for key water heater safety components. Use it to stay on schedule and reduce risks proactively.

| Component | Recommended Interval | Why It Matters |

|---|---|---|

| T&P (Temperature & Pressure) Valve | Every 6 months | Ensures valve opens freely and discharges excess pressure correctly |

| Expansion Tank | Every 3–5 years | Confirms bladder integrity and prevents pressure buildup in closed systems |

| Annual Full Safety Inspection | Once per year | Checks venting, straps, drain pans, electrical, bonding, and fixture clearances |

3 Practical Tips for Safer Hot Water Systems

Quick Monthly T&P Valve Test

Set a calendar reminder and perform a simple lever lift once monthly. Wear gloves because released water feels extremely hot. Look for strong flow; weak dribbles indicate mineral deposits or restrictions. Close the lever smoothly and watch for continued dripping afterward. Contact our team if the valve sticks or fails to reseal properly.

Expansion Tank Damage Check

Gently tap the expansion tank near both ends to gauge air volume. A hollow upper sound and solid lower sound signal correct bladder position. Hearing solid thuds everywhere suggests waterlogging and imminent failure. We can recharge or replace the tank in under an hour. Early attention prevents pressure spikes that damage heaters and fixtures.

Warning Signs on Tankless Units

A tankless water heater will typically display clear error codes when sensors detect abnormal heating or flow conditions. One recent call involved a unit flashing code 29—our tech found a spiderweb in the vent fan and scale deposits in the inlet screen. Burner noise, cold sandwiches, or soot on vents also signal pending issues. Prompt service prevents costly downtime and ensures safe year-round operation.

Benefits Beyond Safety: Efficiency, Compliance, and Peace of Mind

Safety upgrades often boost efficiency by allowing lower standby losses and tighter combustion control. Expansion tanks reduce valve weeping, saving water and energy. Documented compliance lowers insurance premiums and speeds claims after disasters. Families sleep better knowing the system meets current standards and runs reliably. These combined gains usually outweigh upfront costs within a few years.

FAQ: Water Heater Safety Upgrades Explained

What is the lifespan of a T&P valve and how often should it be tested?

Manufacturers design most T&P valves to last around five years under normal conditions. Mineral-rich water or frequent lift cycles can shorten that timeline considerably. We recommend annual testing along with monthly homeowner lever lifts for added assurance. Replace the valve immediately if it drips continuously or fails to open during a test.

Do all homes need an expansion tank, or only some?

Homes with closed plumbing systems definitely require an expansion tank for safe operation. Pressure-reducing valves, backflow preventers, or check valves create a closed system automatically. Open systems sometimes vent excess pressure through municipal mains, yet rules still vary locally. We measure static and dynamic pressure to decide whether the upgrade makes sense.

Can I install a mixing valve myself or should a plumber do it?

Handy homeowners can install mixing valves when they understand soldering, pipe sizing, and code clearance. Improper orientation or temperature calibration can negate scald protection benefits instantly. We guarantee correct placement, leak-free joints, and documented temperature verification during professional installations. Remember that some jurisdictions require licensed plumbers to handle any valve modifications near heaters.

What happens if my water heater doesn’t meet updated safety codes?

Insurers may deny claims stemming from accidents linked to non-compliant equipment. Home inspectors often flag outdated setups, forcing last-minute repairs during property sales. Code officials can issue fines or red-tag dangerous heaters until upgrades occur. Proactive improvements cost less than emergency replacements and preserve household safety year-round.

Making Safety a Plumbing Priority

Safety evolves as building science, materials, and regional hazards change. We monitor code updates and manufacturer bulletins to stay ahead of risks. Offering proactive assessments ensures homeowners never chase emergencies or compromise comfort. Routine upgrades protect property, save energy, and foster community resilience. Reach out to North Fort Myers Plumbing Inc. today and schedule your safety review.

- Chloramine in Lee County Water: Understanding Its Impact on Rubber Gaskets, Water Heater Elements, and Plumbing Lifespan. - December 4, 2025

- Plumbing Durability for SWFL Rental Properties: Choosing Fixtures and Systems That Withstand High-Occupancy Wear and Tear - November 25, 2025

- Flo Smart Leak Protection for Cape Coral & Fort Myers Seasonal Homes - November 18, 2025